Bio-Adaptive Arm Brace

CAD design | additive manufacturing | Rhino3D and Grasshopper modelling | wearable design

3D-Printed Custom-Fitted Arm Support

3D-Printed Custom-Fitted Arm Support

roles: designer | 3D printing manufacturing | business validation | documentation | design thinking

Motivation

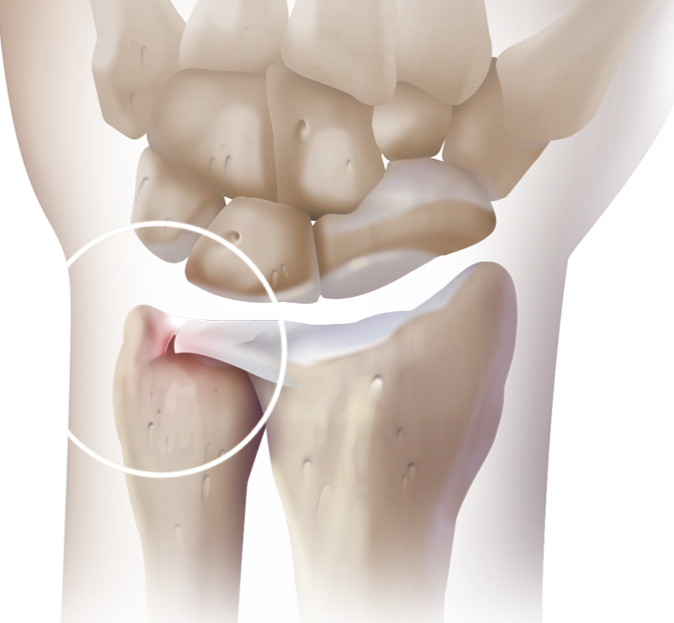

Wrist injuries caused by fall-on-an-outstretched-hand (FOOSH) impacts are common across many athletic disciplines, including board sports, skating, field sports, and training environments where athletes frequently absorb impact through the upper extremities. Injuries including Triangular Fibrocartilage Complex (TFCC) tears and forearm fractures affect both recreational and competitive athletes who train multiple times per week, often resulting in pain, reduced confidence, and prolonged recovery. According to a 2025 Global Burden of Disease Study, there are approximately 31.9 million forearm fractures per year, many of which are caused by FOOSH-type falls.

Fall On An Outstretched Hand (FOOSH)

Triangular Fibrocartilage Complex (TFCC) Tear

Although the global wrist-brace market is large and continues to grow, many existing athletic braces remain bulky, restrictive, and uncomfortable during extended use — particularly when worn under gloves or other protective equipment. Factors such as sweat buildup, temperature variation, and poor fit further limit athlete compliance and performance. As elite and recreational athletes prepare for increasingly competitive environments, including major international events such as the upcoming 2026 Winter Olympics, demand is rising for performance-oriented protective solutions. Athletes are seeking wrist support that is lightweight, flexible, supportive, visually aligned with modern sports culture, and produced sustainably while adapting to individual anatomy. The Bio-Adaptive Arm Brace was motivated by the opportunity to address these gaps through a custom-fitted, athlete-centered wrist brace that enhances protection without compromising mobility or performance.

The brace is bio-adaptive in that its geometry is generated directly from the user’s arm anatomy, allowing the form, fit, and structural density to adjust parametrically to individual biological variation. This approach moves beyond standardized, one-size-fits-all supports and enables targeted reinforcement, comfort, and breathability where it is most needed. Within a global wrist-brace market valued at $1.5 billion — narrowing to approximately $150 million in the premium and custom sports segment — this project identifies a clear opportunity for a novel, performance-driven arm-brace solution rooted in anatomical data and computational design.

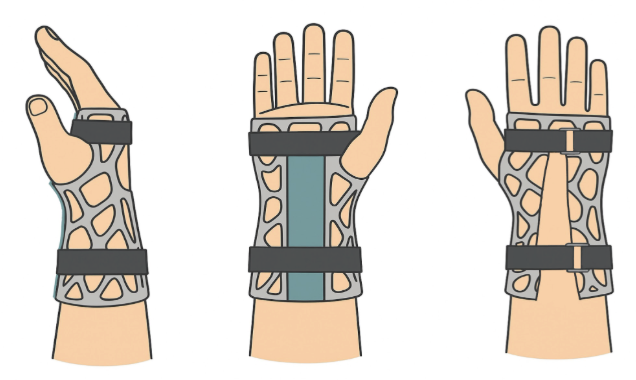

Current Rigid Arm Brace Form Factors

The Flexible Bio-Adaptive Arm Brace

Methodology

Design

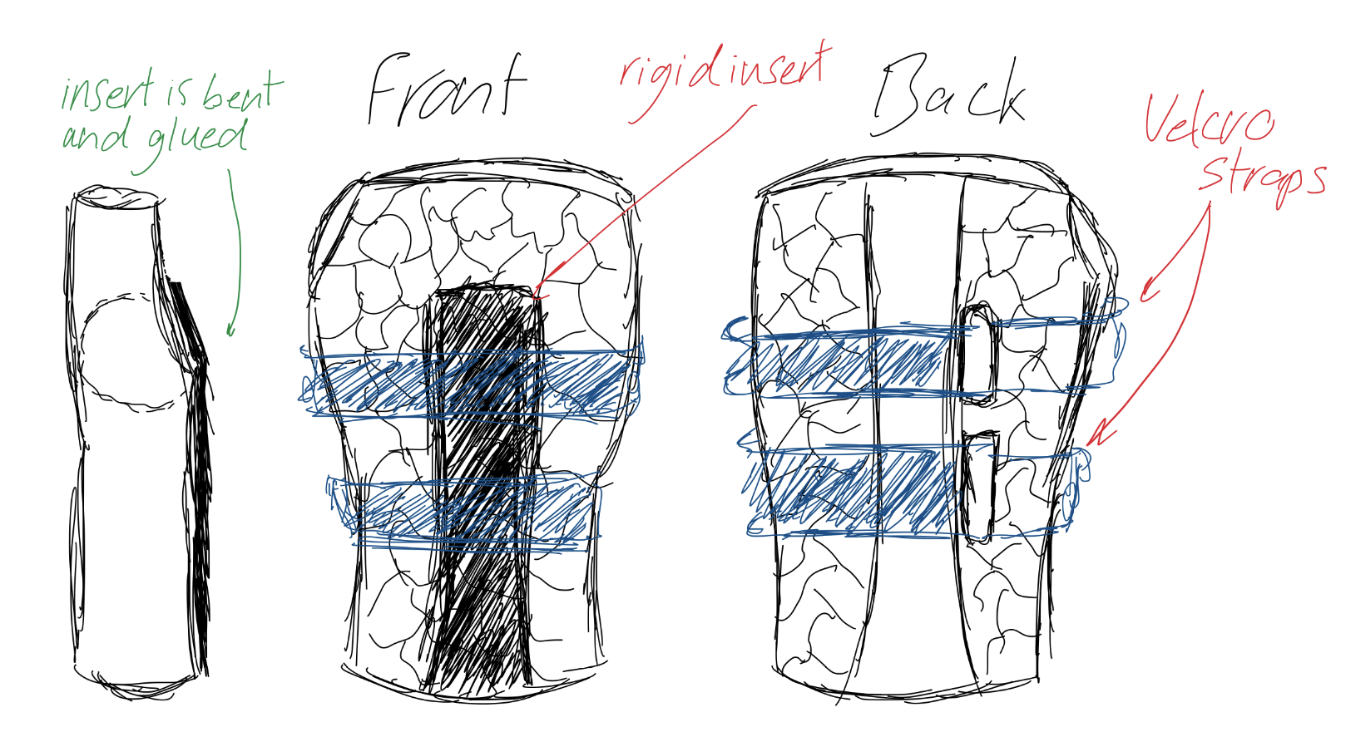

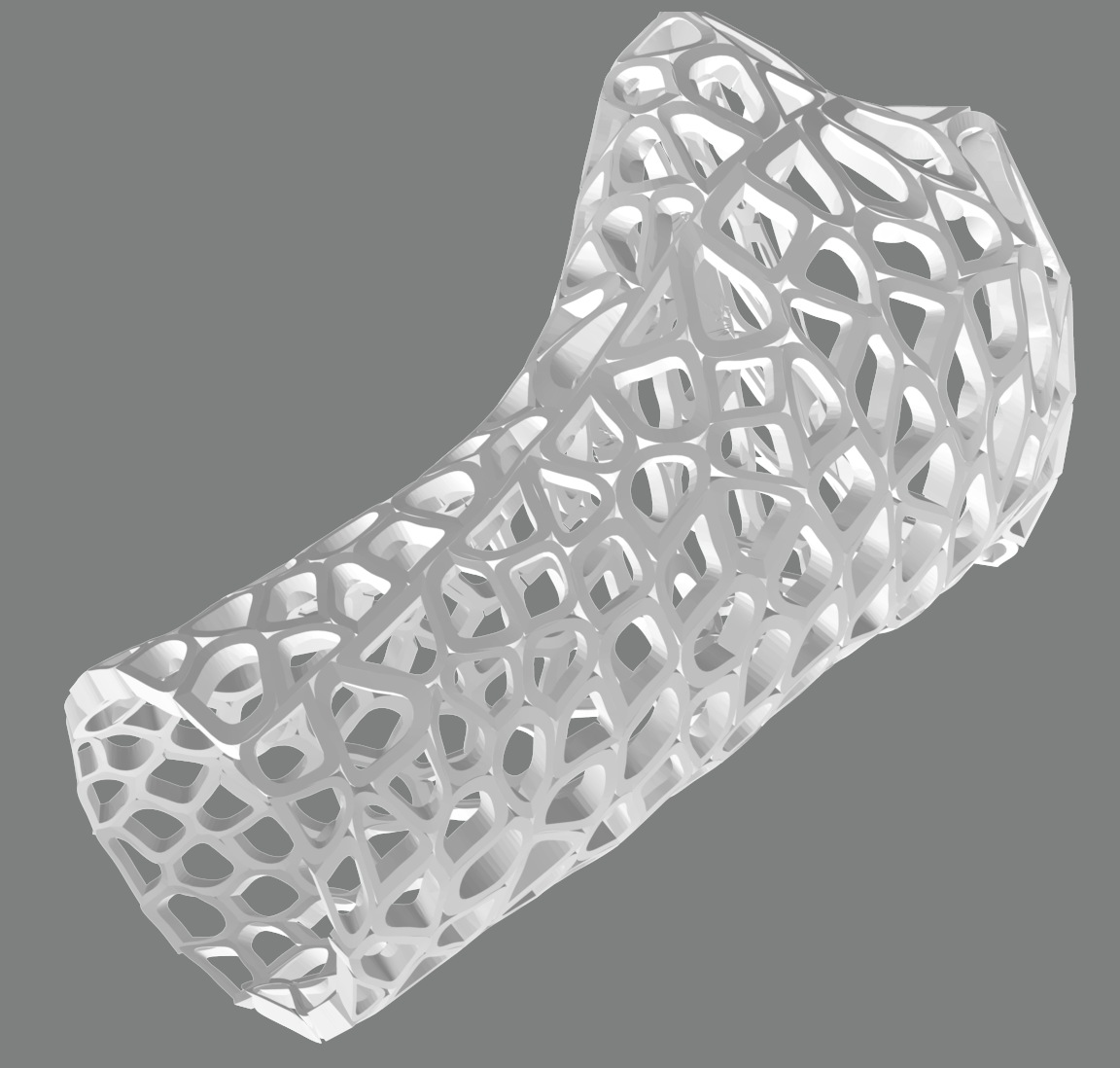

The design process began with athlete-centered research to identify common injury mechanisms, performance needs, and usability challenges across wrist-intensive sports. Early ideation explored multiple levels of fit and rigidity, revealing that neither fully rigid nor overly flexible solutions adequately support athletic movement. The final design prioritizes breathability and support in critical load-bearing regions while maintaining a slim, low-profile form suitable for use under gloves or protective gear. A Voronoi lattice structure was selected based on prior biomechanical and additive manufacturing research, as it optimizes strength-to-weight ratio, evenly distributes forces, reduces stress concentrations, and enhances comfort through improved airflow. Parametric modeling using Rhino and Grasshopper enabled rapid iteration and systematic balancing of key trade-offs, including comfort versus rigidity, slim profile versus padding, and structural strength versus breathability.

The Arm Brace Design

Breathable and Supported in Critical Areas:

Custom-Fitted

Comfortable

Anti-Bacterial

Supportive

Design Compromises:

Comfort vs. Rigidity

Slim Profile vs. Padding

Custom Fit vs. Speed of Production

Breathability vs. Strength

Initial Design Sketches

Brace Design Fittings

Customization

Customization initially began with a personalized arm scan using the CR-Scan Ferret Pro 3D Scanner, capturing the athlete’s wrist and forearm geometry to enable a highly individualized fit. While this approach provided detailed anatomical data, it introduced challenges related to scan cleanup, alignment, and repeatability. As a result, the workflow evolved toward using an online 3D arm model overlaid brace-fitting approach, which allowed more efficient integration with the parametric design environment. This method enabled consistent scaling, cleaner geometry, and faster iteration while still preserving anatomical accuracy. The overlaid arm model was used to refine brace geometry, support placement, and lattice distribution through multiple fitting attempts, demonstrating a scalable customization strategy suitable for mass-customized athletic equipment.

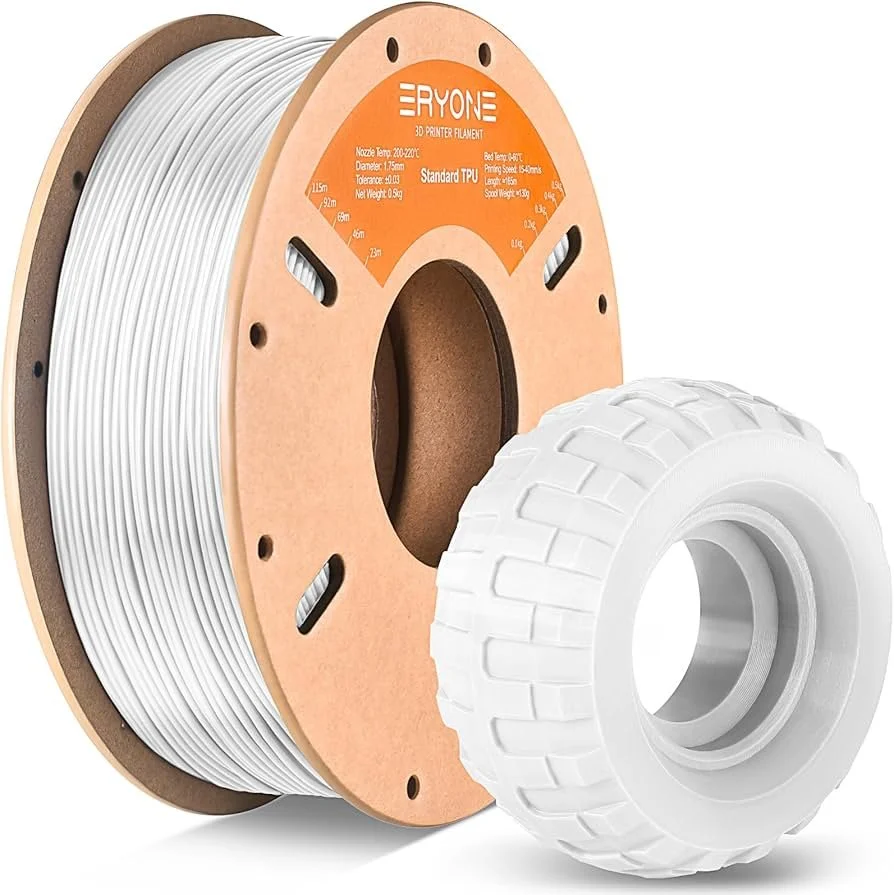

Materials

A range of rigid and flexible 3D printing materials were evaluated, including fiber-reinforced nylons, high-strength resins, and elastomeric polymers, to assess their suitability for athletic wrist support. While rigid materials offered high stiffness and structural stability, they were less appropriate for dynamic athletic movement and prolonged wear due to reduced comfort and adaptability. Flexible thermoplastic polyurethane (TPU 85A/95A) was selected as the primary material for the adult brace due to its durability, elasticity, skin compatibility, and ability to maintain performance under repetitive motion and varying environmental conditions. TPU also supports complex lattice structures effectively, enabling the integration of flexibility, breathability, and targeted structural support within a single material system.

TPU95A 3D Printing Filament

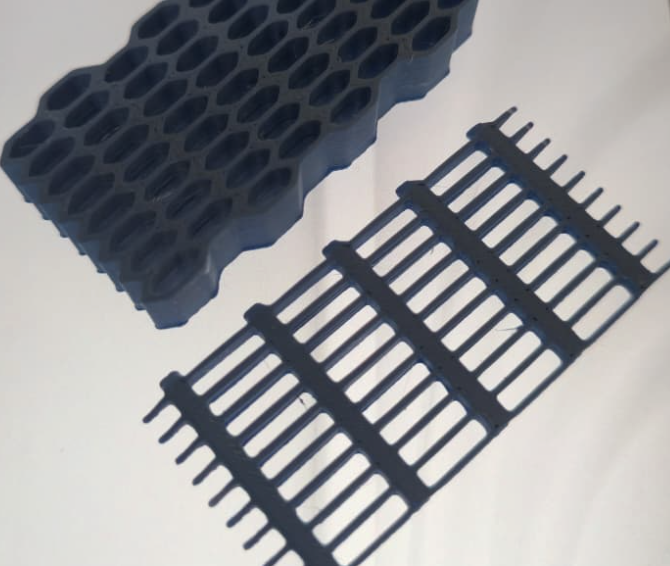

TPU and PLA Sample Prints

Material Samples: PETG and Carbon Fibre

To inform this material decision, several physical samples were fabricated and tested. Among these was a fully PLA prototype, intentionally produced with higher rigidity to explore applications requiring increased stiffness, such as child wrist support or lower-impact use cases where controlled motion limitation is desirable. These comparative material samples played a key role in validating performance trade-offs and demonstrating the adaptability of the design to different user groups and support requirements.

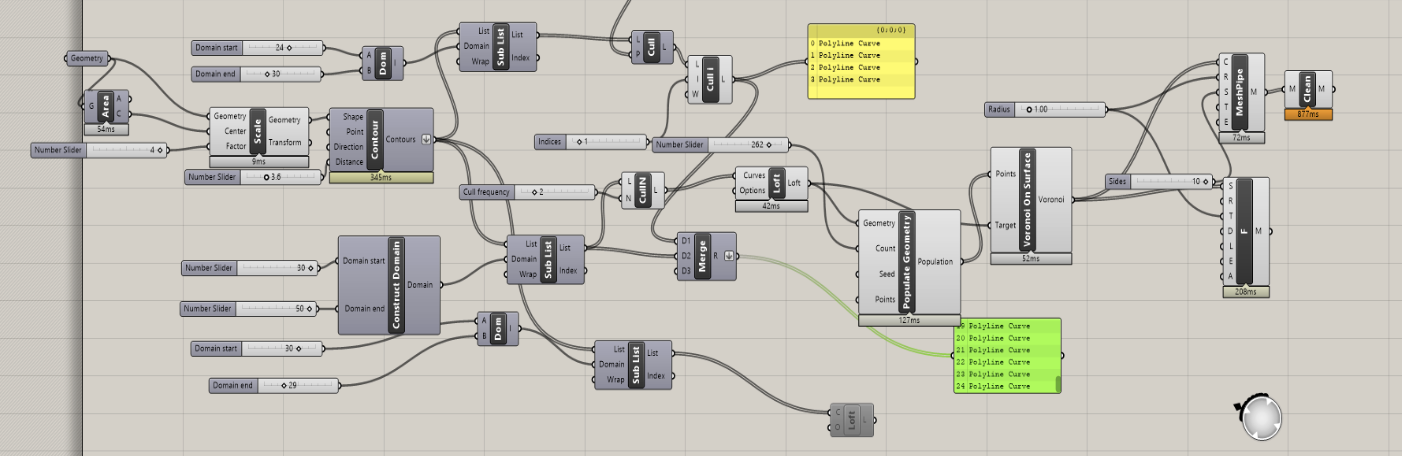

Design and Software

Final Arm Brace 3D Rendering

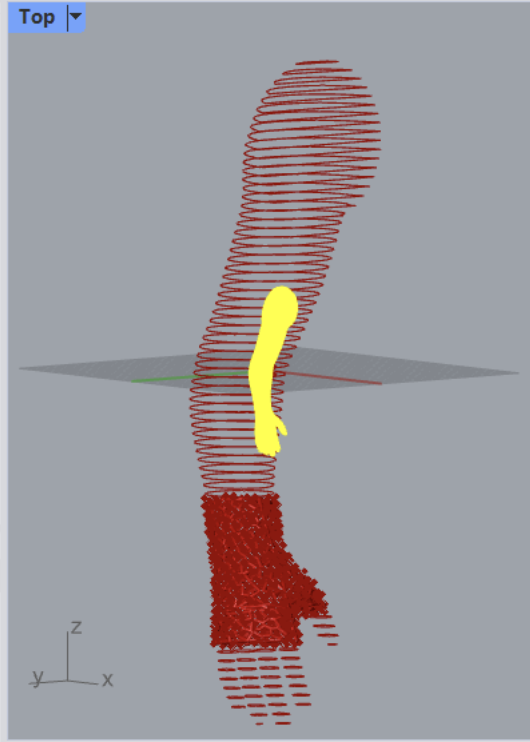

The process begins by importing a 3D model of the arm, which is used as a reference to build the brace directly around the body’s actual form. The arm geometry is first scaled slightly to create clearance for comfort and printing tolerance. The model is then sliced into a series of contour curves along its length, which define the main structural sections of the brace. Unnecessary contours are removed and the remaining curves are organized and lofted together, forming a smooth surface that wraps naturally around the arm. Next, points are populated across this surface and used to generate a Voronoi pattern, creating openings that improve breathability while reducing material. Finally, the surface is given thickness and smoothed, resulting in a lightweight, custom-fit arm brace ready for 3D printing.

Import 3D Arm Model with Fitted Brace Designed

Rhinoceros 3D Grasshopper Modelling

Calibration

Arm Brace Scaled to Adult Size

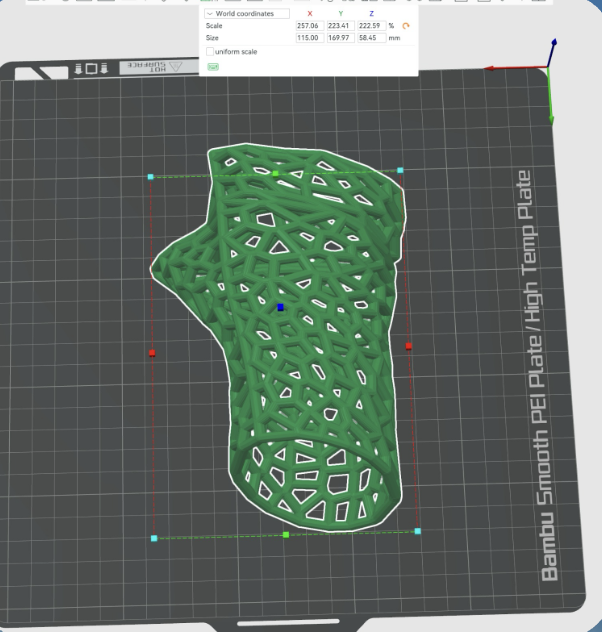

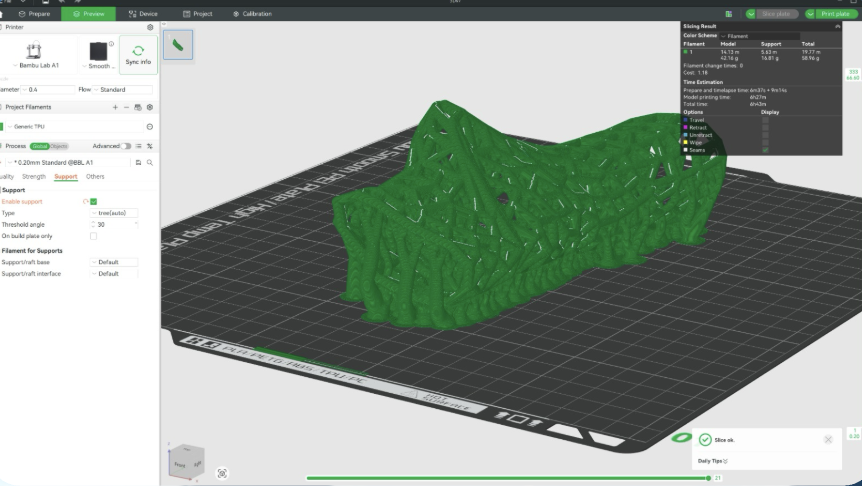

Generated 3D Printed Supports on Bambu Studio

Before printing, the arm brace model is imported into Bambu Studio for calibration and slicing. The first step is scaling, where the model is adjusted to adult arm dimensions using uniform scale and verified against real-world measurements to ensure a proper fit. The brace is then oriented on the build plate to minimize overhangs and improve surface quality. Automatic support generation is enabled to support the complex Voronoi geometry, ensuring structural stability during printing while remaining easy to remove. Slicer settings such as layer height, wall thickness, infill, and material selection are reviewed to balance flexibility, strength, and print time. This calibration stage ensures the brace is accurately sized, properly supported, and fully optimized for reliable 3D printing.

3D Printing

Bambu Printer: A1

3D Printing Time: 12.5 hour

To 3D print the arm brace, there were many options. However, the A1 Bambu Printer’s specs were the most appropriate for the TPU materials I wanted to use for support flexibility and strong, fatigue-resistant brace parts. It also had a built-in camera to track 3D printing progress so you could monitor it remotely during the 12.5 hour print. Lastly, compared to other printers I’ve used, like Creality, the Bambu printer’s auto-cleaning nozzle system was an asset to avoid filament spaghettification issues. Overall, the print took ~12.5 hours and took several hours to manually remove the supports with a pair of pliers.

Final Product

Manually Removing Supports After 3D Printing

3D Printed Arm Braces: Child Size (PLA) [Left] and Adult Size (TPU) [Right]

Future Directions

Future development will focus on refining structural support for higher-impact athletic activities, improving material durability under extreme temperature and moisture conditions, and conducting broader athlete validation studies across sports and training contexts. However, my team (Rawan, Luis, and Salma) and I are proud of the current prototype and as a project that in the future could propose a scalable mass-customization workflow that integrates athlete wrist scanning or size selection, automated parametric CAD adjustment, batch 3D printing of flexible shells, and streamlined finishing and assembly. This approach positions additive manufacturing as a viable production method for personalized athletic protective equipment. Additional future directions include open-sourcing the design to encourage community-driven innovation and accessibility, as well as integrating optional inertial measurement unit (IMU) sensors to provide real-time motion tracking, impact monitoring, and data-informed injury prevention and rehabilitation for athletes.